{Addressing rigorous conditions regarding ultracold deployments entails professional valve development. Our cold 3-way circular piece options are produced to provide unwavering functionality even at deep-freeze temperatures, typically below -150°C. These assemblies offer outstanding conveyance regulation in liquefied fluids such as nitrogen, oxygen, and argon, frequently adopted in markets like LNG, scientific equipment, and therapeutic facilities. Our team highlight strong construction, including smooth-running closure elements and accurate fabrication, to validate hermetic running. Explore the advantages of optimizing your arctic system with our modern 3-way rotational mechanism answers.

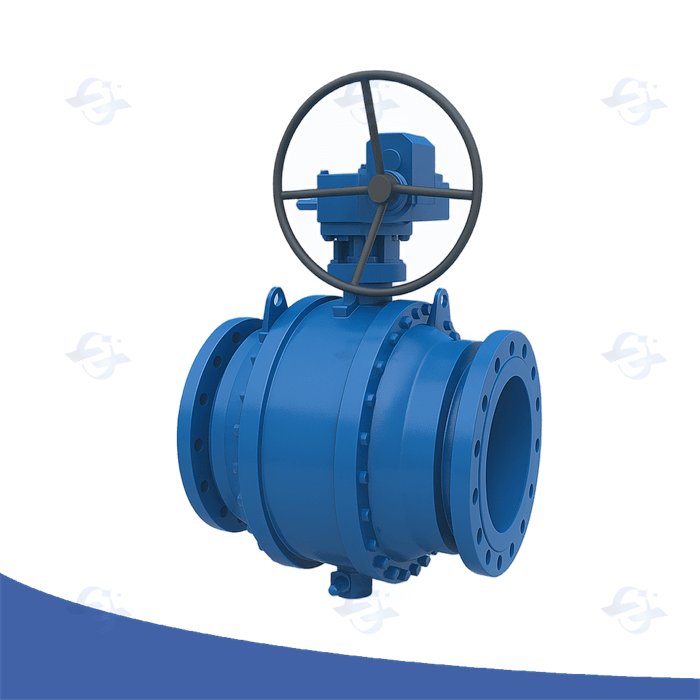

High-Performance Dual Closure and Drain Circular Valve Arrays

In terms of vital processes, particularly where outflow is restricted, advanced double block and bleed sphere valves offer unmatched protection. This specialized design incorporates two independent ball valve seals, plus a bleed hole, allowing for ascertainment of the total shut-off and discovery of any conceivable exfiltration. Generally employed in petroleum tasks, fabrication transformation, and arctic environments, these valves noticeably augment service reliability and cut the exposure of habitat consequence.

T-Way Ice-Cold Circular Instrument Architecture

Such design of tri-channel frosty ball apparatus presents a specific engineering concern. These components are typically employed in essential industrial functions where extreme conditions must be maintained. Key points include ingredient choice, particularly regarding vulnerability at minimal conditions, and the must for secure stopping to inhibit draining of cryogenic compounds. Advanced analysis procedures and thorough development procedures are fundamental to confirm consistent efficiency and lifespan under such challenging working situations.

Cryogenic Switch Function in Vocational Applications

These demanding needs of cryogenic deployments, such as refined natural fuel handling and cooled nitrogen storage, necessitate unfailing actuator systems. Integral block discharge units provide a particularly robust and effective system to achieving zero-leak fastening while facilitating regular maintenance. Their design blends a primary shutoff with a small opening bore, allowing administered pressure venting during cutoff and commencing. This inherent characteristic minimizes continuing product entrapment, thereby ensuring excellent shielding and effectiveness even under the most tough performing situations. Furthermore, the skill to detect bleed transit provides valuable examination data for activity maximization.

Achieving 3-Way Globular Valve Fastening in Tough High-Pressure Situations

Achieving reliable security performance with 3-way globular valves becomes particularly noteworthy when operating within intense pressure situations. The design is required to account for significant impacts and potential seepage pathways. Specialized compositions, often including high-performance metals like rust-resistant steel or exotic alloys, are vital to withhold the extreme conditions. Furthermore, elaborate connection geometries and careful fabrication processes are essential to minimize sagging and guarantee a sealed fastening even under fluctuating strain cycles. Regular check and periodic overhaul programs are as well vital for lastingness and uninterrupted operational efficiency.

Subzero Ball Valve Leakage Prevention Strategies

Minimizing "oozing" from cryogenic "sphere-shaped valves" demands a multifaceted "procedure". Initial "planning" considerations are paramount; material "preference" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "composition", meticulous "assembly" processes – including stringent weld "checks" and non-destructive "evaluation" – are vital to ensure structural integrity and eliminate voids that could become "pathways". A "critical" component is proper "placement"; thermal "tightening" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "inspection" – including periodic "audit" for signs of wear and "restoration" of any identified issues – is indispensable for maintaining a reliable, leak-tight "barrier”. Ultimately, a robust "program" incorporating these elements is necessary to ensure the safe and efficient "functionality" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "deterioration", safety "perils", and costly "breakdown”.

Double-Layer Clamp and Release System Assessment Operations

To certify the integrity and safety of critical piping channels, rigorous dual stopper and discharge mechanism evaluation plans are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation units while simultaneously ensuring the exhaust valve remains functional and correctly discharges any trapped liquid. A common approach is to utilize a pressure analysis where the system is pressurized to its maximum working pressure, and the escape rate around the closed units is meticulously checked. The discharge device's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of trial results, including any abnormalities observed, is required for maintaining a reliable procedure.

Comprehending Integral Block Release Device Operation

So as to accurately handle pressure installations, a exhaustive understanding of integral block drain instrument functionality is wholly crucial. These tailored units principally operate to successfully expel unwanted force from a configuration during defined engaged stages. A usual placement includes a locked portion linked to the leading power source, allowing one regulated outflow should mandatory. The elemental construction cuts down on the exposure of pressure surge, guarding both the tools and the proximate environment. Regular examination and servicing are important to confirm peak operation.

Selecting the Ideal 3-Way Ball Valve for Cryogenic Fluids

Electing a proper 3-three-ball gate for cryogenic applications demands careful inspection of several critical criteria. The extremely low cold levels inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present uncommon challenges. Material choice is paramount; only materials with proven fitting and ductility at these temperatures, such as oxidation-resistant steel grades like 304L or 316L, or specialized brass alloys, should be examined. Furthermore, the apparatus's sealing efficiency is vital to prevent escapes, requiring innovative stem sealing structures and low-temperature solutions. Finally, pressure measures and actuation methods, taking into account potential pressure jumps, must be carefully matched to the system's conditions. Neglecting these details can lead to grave failure and safety exposures.

Icy Globe Valve Composition Harmony Compendium

Picking the appropriate component for cryogenic globe valves is paramount, given the intense temperatures involved. This directory highlights common compounds and their reaction when exposed to cryogenic fluids such as liquid nitrogen, fluid helium, and oxygen. Stainless steels, particularly types 304 and 316, often demonstrate adequate durability and degradation resistance, though martensitic metals require careful consideration regarding susceptibility. Aluminum alloys can be suitable for certain applications, however, their malleability and tolerance to specific chemicals needs complete evaluation. Copper alloys, while offering some advantages, may exhibit declined competence at these minimized temperatures. Consultation with providers and comprehensive assessment is essential to ensure continuity and dependability in cryogenic applications.

Increasing Dual Block and Bleed Application Operation

Gaining optimal effectiveness in twin seal and vent applications hinges on a multifaceted plan. Careful analysis of device selection is indispensable, with a focus on element compatibility and strain classification. Regular monitoring of bypass corridors for impedance is mandatory, often requiring the use of professional testing apparatus. Furthermore, practice tuning—including inspection of transport rates and force gap—can noticeably improve overall setup firmness and reliability. Finally, adherence to producer directives and the carrying out of a detailed overhaul schedule are indispensable for long-term trustworthiness and lifespan.

Integral Block Bleed Valves

Integral Block Bleed Valves