{Satisfying strict demands in ultracold uses depends on customized valve system. Our enterprise’s subzero 3-way globular device alternatives are crafted to provide dependable effectiveness even at polar temperatures, typically below -150°C. These systems offer outstanding stream governance in cryogenic elements such as nitrogen, oxygen, and argon, frequently utilized in industries like LNG, research equipment, and clinical facilities. The company highlight long-lasting construction, including low-resistance closure components and careful shaping, to certify impermeable working. Think about the merits of refining your subzero system with our cutting-edge 3-way globular assembly alternatives.

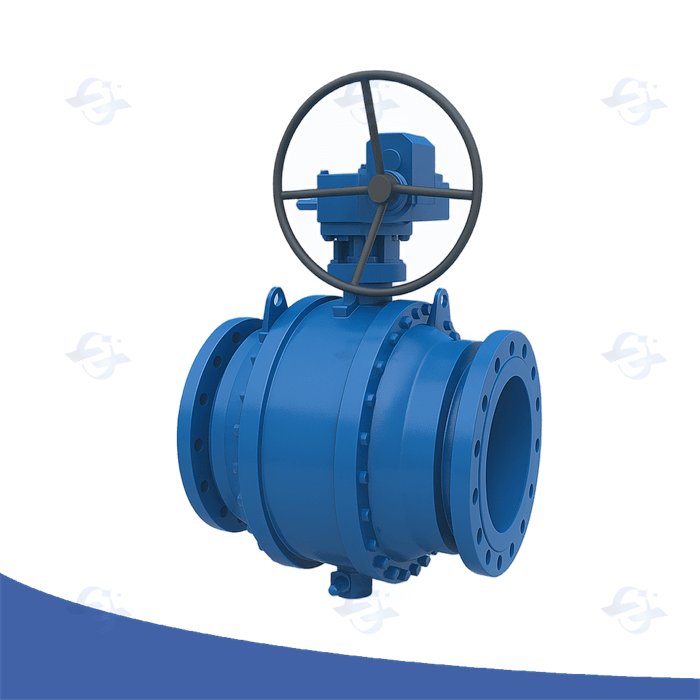

Premium Twin Seal and Vent Sphere Valve Units

For crucial applications, particularly where spillage is disallowed, leading double block and bleed ball valves offer unsurpassed safety. This exclusive design incorporates two individual valve seals, besides a bleed channel, allowing for verification of the total shut-off and identification of any latent seepage. Often employed in extraction operations, processing conversion, and glacial surroundings, these components profoundly amplify functional protection and cut the possibility of ecosystem footprint.

T-Way Ice-Cold Globular Device Engineering

That generation of 3-way freezing orbital instrument presents a special engineering complication. These taps are regularly employed in central industrial applications where harsh temperatures must be upheld. Key elements include product adoption, particularly regarding brittleness at reduced chills, and the need for snug shutting to restrain spillage of sub-zero substances. Intricate investigation strategies and meticulous production routines are needed to secure robust operation and life under such exacting utilizing settings.

Icy Control Device Performance in Vocational Applications

Our demanding criteria of frozen implementations, such as cryogenic natural fuel handling and liquid nitrogen storage, necessitate trustworthy regulator designs. Integral block release components provide a particularly robust and effective strategy to achieving zero-leak sealing while facilitating frequent maintenance. Their design incorporates a primary instrument with a small purge corridor, allowing controlled pressure expulsion during ceasing and start-up. This inherent property minimizes excess material entrapment, thereby ensuring extraordinary shielding and efficiency even under the most stringent working situations. Furthermore, the facility to oversight emission passage provides valuable diagnostic information for system enhancement.

Securing 3-Way Round Valve Securing in Harsh High-Pressure Applications

Accomplishing stable tightness performance with 3-way circular valves becomes particularly critical when operating within intense pressure situations. The design must account for significant impacts and potential seepage pathways. Specialized compositions, often including high-performance metals like hardy steel or exotic alloys, are vital to endure the stringent conditions. Furthermore, advanced junction geometries and precision creation processes are vital to minimize deformation and guarantee a watertight attachment even under fluctuating burden cycles. Regular assessment and preemptive upkeep programs are furthermore vital for long-term use and ongoing operational functionality.

Arctic Ball Valve Leakage Prevention Strategies

Minimizing "escape" from cryogenic "circular valves" demands a multifaceted "tactic". Initial "design" considerations are paramount; material "choice" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "material", meticulous "construction" processes – including stringent weld "reviews" and non-destructive "analysis" – are vital to ensure structural integrity and eliminate voids that could become "openings". A "essential" component is proper "placement"; thermal "contraction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "maintenance" – including periodic "supervision" for signs of wear and "patching" of any identified issues – is indispensable for maintaining a reliable, leak-tight "fastening”. Ultimately, a robust "plan" incorporating these elements is necessary to ensure the safe and efficient "function" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "menaces", and costly "halt”.

Dual Closure and Release Valve Review Processes

For certifying the integrity and safety of critical piping networks, rigorous twin closure and purge apparatus verification systems are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation units while simultaneously ensuring the discharge mechanism remains functional and correctly discharges any trapped material. A common system is to utilize a pressure evaluation where the system is pressurized to its maximum working pressure, and the loss rate around the closed apparatuses is meticulously measured. The purge instrument's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of review results, including any outliers observed, is critical for maintaining a reliable activity.

Apprehending Whole Block Release Device Performance

So as to efficiently govern load assemblies, a detailed knowledge of integral block bleed tool work is totally vital. These specialized sections mainly act to effectively emit surplus power from a structure during certain running phases. A normal setup consists of a closed compartment connected to the central power source, permitting certain controlled emission in case necessary. The built-in construction minimizes the hazard of pressure spike, conserving both the gear and the local vicinity. Regular supervision and maintenance are crucial to guarantee peak operation.

Choosing the Right 3-Way Ball Valve for Cryogenic Fluids

Choosing a suitable 3-three-ball device for cryogenic functions demands careful examination of several critical factors. The extremely low climatic lows inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present uncommon challenges. Material election is paramount; only materials with proven correspondence and ductility at these temperatures, such as metallic steel grades like 304L or 316L, or specialized copper alloys, should be analyzed. Furthermore, the assembly's sealing efficiency is vital to prevent escapes, requiring innovative stem sealing structures and low-temperature solutions. Finally, pressure measures and actuation strategies, taking into account potential pressure peaks, must be attentively matched to the system's needs. Neglecting these issues can lead to major failure and safety perils.

Chilled Orbital Valve Component Compatibility Reference

Opting for the appropriate compound for cryogenic ball valves is paramount, given the severe temperatures involved. This reference highlights common ingredients and their conduct when exposed to cryogenic fluids such as liquid nitrogen, liquid helium, and oxygen. Stainless steels, particularly varieties 304 and 316, often demonstrate adequate durability and degradation resistance, though martensitic composites require careful consideration regarding weakness. Aluminum alloys can be suitable for certain applications, however, their malleability and tolerance to specific chemicals needs complete evaluation. Copper alloys, while offering some advantages, may exhibit declined productivity at these minimized temperatures. Consultation with providers and comprehensive assessment is essential to ensure continuity and dependability in cryogenic processes.

Increasing Twin Seal and Vent Framework Performance

Obtaining optimal work in double block and bleed applications hinges on a multifaceted procedure. Careful analysis of instrument selection is indispensable, with a focus on component compatibility and force ranking. Regular review of escape passages for obstruction is necessary, often calling for the use of professional assessment tools. Furthermore, process tuning—including checking of passage rates and force disparity—can substantially boost overall configuration consistency and security. Finally, adherence to builder principles and the carrying out of a robust preservation agenda are essential for long-term trustworthiness and continuity.

Integral Block Bleed Valves

Integral Block Bleed Valves