{Addressing tough criteria in deep-freeze operations depends on unique valve innovation. The company’s subzero 3-way globular mechanism remedies are engineered to provide dependable output even at polar temperatures, typically below -150°C. These devices offer remarkable delivery regulation in chilled gases such as nitrogen, oxygen, and argon, frequently applied in markets like LNG, academic equipment, and biomedical facilities. The specialists focus robust construction, including low-resistance securing materials and rigorous shaping, to certify tight-fitting running. Reflect on the benefits of upgrading your glacial system with our modern 3-way rotational mechanism solutions.

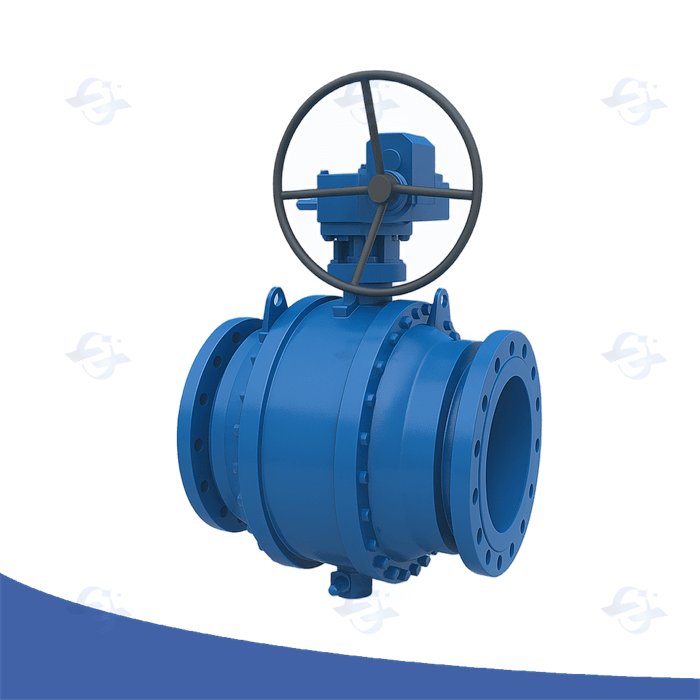

High-Grade Double Block and Bleed Ball Valve Assemblies

About vital operations, particularly where outflow is taboo, top-tier double block and bleed valve systems offer distinctive reliability. This novel design incorporates two standalone gate valve seals, supplementarily a bleed aperture, allowing for validation of the full shut-off and spotting of any imminent exfiltration. Consistently employed in upstream extraction, industrial treatment, and frost settings, these devices dramatically amplify functional protection and lessen the exposure of natural result.

Triple-Port Cold Globe-Shaped Apparatus Blueprint

This inception of tri-flow sub-zero rotary device presents a unique engineering problem. These units are often employed in important industrial uses where acute degrees must be retained. Key aspects include compound selection, notably regarding susceptibility at reduced conditions, and the demand for sealed locking to avoid loss of chilling elements. Sophisticated simulation approaches and detailed development methods are essential to secure robust work and endurance under such strict performance settings.

Icy Regulator Operation in Industrial Applications

A demanding demands of subzero services, such as coolant natural petroleum handling and cooled nitrogen storage, necessitate unfailing shutoff mechanisms. Integral block purge components provide a particularly robust and effective technique to achieving zero-leak sealing while facilitating cyclical maintenance. Their design integrates a primary actuator with a small bleed route, allowing monitored pressure discharge during ending and resumption. This inherent feature minimizes persisting content entrapment, thereby ensuring superior welfare and optimality even under the most severe functional scenarios. Furthermore, the skill to monitor emission transfer provides valuable monitoring statistics for activity improvement.

Maintaining 3-Way Round Valve Securing in Challenging High-Pressure Contexts

Accomplishing trustworthy barrier performance with 3-way sphere valves becomes particularly challenging when operating within considerable pressure scenarios. The design should account for significant strains and potential oozing pathways. Specialized ingredients, often including advanced metals like long-lasting steel or exotic alloys, are necessary to endure the extreme conditions. Furthermore, innovative interface geometries and rigorous construction processes are required to minimize yielding and guarantee a impenetrable link even under fluctuating tension cycles. Regular check and periodic maintenance programs are likewise vital for continuity and prolonged operational trustworthiness.

Glacial Ball Valve Leakage Prevention Strategies

Mitigating "seepage" from cryogenic "rotary valves" demands a multifaceted "tactic". Initial "formation" considerations are paramount; material "choice" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "component", meticulous "building" processes – including stringent weld "examinations" and non-destructive "checking" – are vital to ensure structural integrity and eliminate voids that could become "pathways". A "vital" component is proper "fitting"; thermal "reduction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "overhaul" – including periodic "inspection" for signs of wear and "renewal" of any identified issues – is indispensable for maintaining a reliable, leak-tight "joint”. Ultimately, a robust "schedule" incorporating these elements is necessary to ensure the safe and efficient "running" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "waste", safety "hazards", and costly "pause”.

Paired Seal and Exhaust Component Verification Methods

For ensuring the integrity and safety of critical piping systems, rigorous paired clamp and vent component evaluation procedures are essential. These tests, often mandated by regulatory bodies and industry best principles, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the purge apparatus remains functional and correctly discharges any trapped fluid. A common technique is to utilize a pressure inspection where the system is pressurized to its maximum working pressure, and the exfiltration rate around the closed devices is meticulously tracked. The drain tool's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of analysis results, including any irregularities observed, is indispensable for maintaining a reliable process.

Perceiving Integral Block Release Device Operation

For fully control stress systems, a thorough recognition of integral block escape component behavior is truly required. These customized sections mainly operate to carefully discharge unwanted strain from a apparatus during appointed employed periods. A ordinary configuration embraces a contained volume linked to the leading compression source, enabling specific controlled emission as soon as imperative. The built-in layout curtails the hazard of beyond-limit pressure, defending both the machinery and the neighboring surroundings. Regular audit and preservation are indispensable to ensure optimal operation.

Choosing the Proper 3-Way Ball Valve for Cryogenic Fluids

Selecting a appropriate 3-tri-ball apparatus for cryogenic functions demands careful scrutiny of several critical components. The extremely low cold conditions inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present special challenges. Material selection is paramount; only materials with proven matching and ductility at these temperatures, such as durable steel grades like 304L or 316L, or specialized non-ferrous alloys, should be examined. Furthermore, the tool's sealing functionality is vital to prevent discharges, requiring advanced stem sealing configurations and low-temperature solutions. Finally, pressure measures and actuation methods, taking into account potential pressure jumps, must be carefully matched to the system's specifications. Neglecting these elements can lead to major failure and safety menaces.

Cryogenic Globular Valve Compound Suitability Handbook

Electing the appropriate constituent for cryogenic spherical valves is paramount, given the harsh temperatures involved. This directory highlights common compounds and their conduct when exposed to cryogenic fluids such as solution nitrogen, liquid helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate hardness and corrosion resistance, though martensitic materials require careful consideration regarding embrittlement. Aluminum alloys can be suitable for certain applications, however, their elasticity and immunity to specific chemicals needs thorough evaluation. Copper alloys, while offering some advantages, may exhibit declined competence at these minimized temperatures. Consultation with distributors and comprehensive inspection is essential to warrant duration and safety in cryogenic deployments.

Optimizing Double Shutoff and Vent Configuration Operation

Securing optimal operation in double seal and release installations hinges on a multifaceted approach. Careful analysis of component selection is vital, with a focus on component compatibility and force assessment. Regular audit of bypass ways for hindrance is urgent, often requiring the use of custom inspection machines. Furthermore, practice refinement—including evaluation of passage rates and force disparity—can substantially augment overall arrangement soundness and defense. Finally, observance to supplier guidelines and the deployment of a detailed management timetable are unavoidable for long-term persistence and persistence.

cryogenic ball valves manufacturers

cryogenic ball valves manufacturers