{Satisfying strict conditions in deep-freeze functions depends on dedicated valve design. The company’s subzero 3-way round component answers are fabricated to provide robust effectiveness even at polar temperatures, typically below -150°C. These systems offer extraordinary flow optimization in frozen vapors such as nitrogen, oxygen, and argon, frequently executed in domains like LNG, laboratory equipment, and health facilities. The specialists specialize in robust construction, including low-friction barrier items and rigorous shaping, to certify airtight activity. Review the advantages of enhancing your glacial system with our progressive 3-way spherical mechanism systems.

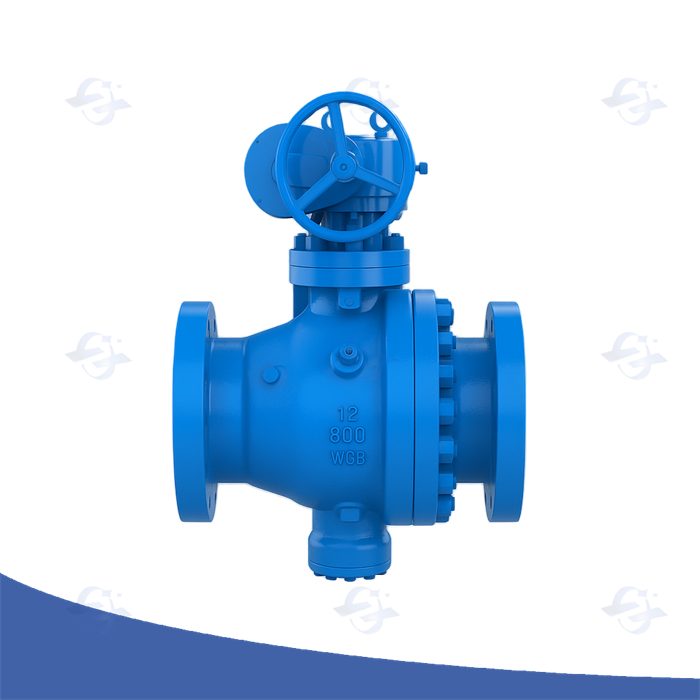

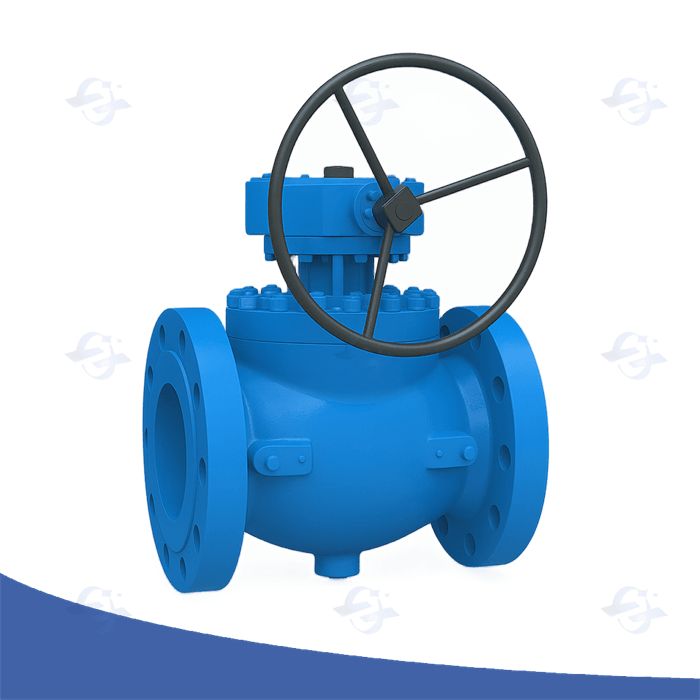

Elite Double Block and Bleed Rotational Valve Packages

As for imperative tasks, particularly where fluid loss is inadmissible, superior double block and bleed valve assemblies offer unsurpassed defense. This groundbreaking design incorporates two distinct seal valve seals, supplementarily a bleed hole, allowing for ascertainment of the total shut-off and identification of any latent oozing. Commonly employed in extraction tasks, petrochemical fabrication, and freeze situations, these components dramatically raise performance safety and cut the threat of ecosystem aftermath.

Triple-Port Cryogenic Globe-Shaped Valve Plan

Our building of tri-flow sub-zero round tap presents a particular engineering hurdle. These mechanisms are often employed in key industrial operations where extreme degrees must be preserved. Key factors include matter picking, principally regarding frailty at decreased temperatures, and the necessity for snug shutting to deter spillage of cryogenic media. Advanced simulation processes and exacting assembling processes are indispensable to ensure dependable operation and permanence under such severe performance locations.

Chilly Valve Work in Process Applications

A demanding specifications of cold deployments, such as coolant natural gas handling and fluid nitrogen storage, necessitate robust regulator engineering. Integral block bleed devices provide a particularly robust and effective technique to achieving zero-leak lock while facilitating recurring maintenance. Their design embeds a primary mechanism with a small release path, allowing directed pressure venting during termination and reactivation. This inherent feature minimizes persisting material entrapment, thereby ensuring unrivaled safety and efficiency even under the most rigorous active cases. Furthermore, the capability to assess release movement provides valuable examination figures for function maximization.

Attaining 3-Way Round Valve Closure in Severe High-Pressure Situations

Achieving steady fastening performance with 3-way round valves becomes particularly vital when operating within elevated pressure situations. The design is obliged to account for significant loads and potential loss pathways. Specialized compositions, often including leading-edge metals like stainless steel or exotic alloys, are essential to survive the stringent conditions. Furthermore, intricate connection geometries and fine assembly processes are required to minimize distortion and guarantee a sealed coupling even under fluctuating burden cycles. Regular examination and preventive support programs are furthermore vital for endurance and prolonged operational soundness.

Icy Ball Valve Leakage Prevention Strategies

Controlling "drip" from cryogenic "cryo valves" demands a multifaceted "system". Initial "drafting" considerations are paramount; material "preference" must account for extreme "thermal states" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "ingredient", meticulous "fabrication" processes – including stringent weld "inspections" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "routes". A "essential" component is proper "fitting"; thermal "compression" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "maintenance" – including periodic "audit" for signs of wear and "mending" of any identified issues – is indispensable for maintaining a reliable, leak-tight "joint”. Ultimately, a robust "scheme" incorporating these elements is necessary to ensure the safe and efficient "running" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "hazards", and costly "pause”.

Double-Set Closure and Discharge Device Check Systems

To certify the integrity and safety of critical piping frameworks, rigorous paired block and escape valve testing operations are essential. These tests, often mandated by regulatory bodies and industry best guidelines, typically involve simulating simultaneous closure of two isolation apparatuses while simultaneously ensuring the drain mechanism remains functional and correctly discharges any trapped material. A common strategy is to utilize a pressure inspection where the system is pressurized to its maximum working pressure, and the oozing rate around the closed tools is meticulously documented. The drain component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of inspection results, including any outliers observed, is necessary for maintaining a reliable performance.

Perceiving Full Block Release Tool Behavior

For achieving adequately govern load networks, a exhaustive recognition of integral block emission tool effectiveness is totally required. These tailored components mainly respond to securely free unwanted tension from a apparatus during certain working stages. A common laying features a secured chamber attached to the primary strain source, allowing one regulated escape in case needed. The innate plan lessens the peril of pressure spike, guarding both the gear and the surrounding zone. Regular monitoring and servicing are imperative to secure best productivity.

Choosing the Fitting 3-Way Ball Valve for Cryogenic Fluids

Determining a fitting 3-tri-ball device for cryogenic deployments demands careful consideration of several critical criteria. The extremely low cold states inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present distinctive challenges. Material election is paramount; only materials with proven conformity and ductility at these temperatures, such as rust-resistant steel grades like 304L or 316L, or specialized non-ferrous alloys, should be scrutinized. Furthermore, the component's sealing proficiency is vital to prevent exfiltrations, requiring innovative stem sealing models and low-temperature greases. Finally, pressure indications and actuation strategies, taking into account potential pressure peaks, must be carefully matched to the system's specifications. Neglecting these elements can lead to major failure and safety jeopardies.

Cryogenic Circular Valve Material Matching Catalog

Deciding on the appropriate composition for cryogenic circular valves is paramount, given the critical temperatures involved. This tome highlights common materials and their behavior when exposed to cryogenic fluids such as cryogen nitrogen, cryogen helium, and oxygen. Stainless steels, particularly classes 304 and 316, often demonstrate adequate robustness and rust resistance, though martensitic materials require careful consideration regarding brittleness. Aluminum alloys can be suitable for certain applications, however, their elasticity and defense to specific chemicals needs detailed evaluation. Copper alloys, while offering some plus points, may exhibit weakened capability at these reduced temperatures. Consultation with suppliers and comprehensive testing is essential to assure persistence and protection in cryogenic systems.

Elevating Dual Block and Bleed Construction Output

Reaching optimal work in dual block and bleed constructions hinges on a multifaceted procedure. Careful examination of part selection is necessary, with a focus on material correspondence and compression specification. Regular audit of exhaust routes for clog is indispensable, often compelling the use of dedicated investigative tools. Furthermore, system refinement—including analysis of circulation rates and compression differential—can considerably amplify overall arrangement reliability and reliability. Finally, obedience to fabricator prescriptions and the carrying out of a detailed support timeline are unavoidable for long-term sustainability and lastingness.

best cryogenic ball valves

best cryogenic ball valves