Within the universe of industrial activities, preserving the completeness and efficiency of pipelines is vital. Buildup of contaminants within pipes can substantially impair fluid movement, impair commodity standard, and adds to facility expenses. To manage these complications, tube cleansing methods have emerged as remarkably potent answers for effective channel cleaning. A apparatus, commonly a round instrument, is displaced through the passage, skillfully cleaning accumulations and attaining ultimate output

Conduit cleansing procedures deliver myriad assets. They are versatile, capable of scouring conduits of disparate thicknesses and materials. Furthermore, they are competent, accomplishing the operation in a appreciably speedy interval. By reducing downtime and optimizing pipeline effectiveness, pipeline cleaning systems facilitate budget cuts and increased operational efficiency

Health-Driven Pipe Systems:

Maintaining pipeline freshness is vital for supporting commodity integrity and superiority of shipped products. Sanitary pigging methods provide a durable way to accomplish this target. Pigs, customized instruments, are fitted into pipelines to sanitize by taking out residues and contaminants

- Diverse styles of sanitary pigs are found, each manufactured for specific cleaning functions.

- These pigs are developed from elements that follow stringent safe standards.

- Systematic sanitary pigging tasks boost stopping product tainting, prolong pipeline longevity, and strengthen complete performance.

Next-Generation Pigging Applications for Peak Output

Among the landscape of conduit servicing, futuristic pigging mechanisms have become a key means for providing top performance and security. These revolutionary systems deploy sophisticated designs and features to competently flush, survey, and maintain conduits from degradation. From advanced pigs provided with concurrent checking modules to focused pigging tools intended for intricate tasks, advancement in this field is persistently expanding horizons. By implementing these breakthroughs, handlers can markedly increase pipeline strength, cut down downtime, and improve operational effectiveness.

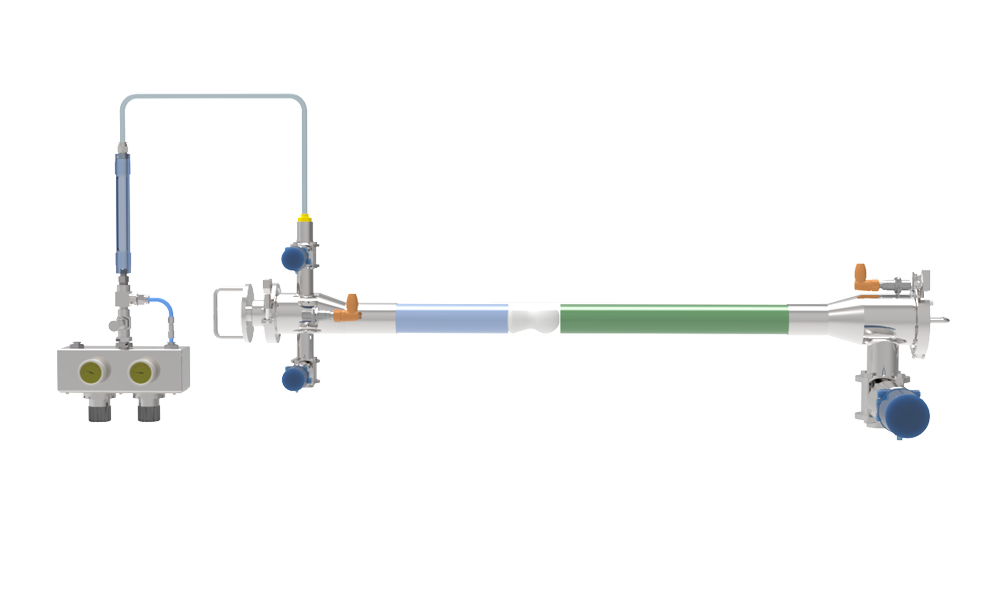

Complete Pigging Solution Design and Installation

A comprehensive pigging system consists of a fundamental technique for pipeline preservation. This system incorporates the deployment of custom devices called pigs, which advance through tubes to flush, check, and protect their firmness. The form underscores features such as tubing diameter, element, pig model, and operational criteria. A carefully planned system assures potent pigging processes while reducing downtime and potential losses. Installation techniques need careful planning, skilled craftsmen, and strict adherence to safety protocols to guarantee a risk-free and positive conclusion

Mechanical Pigging Equipment for Wide Assignments

Professional pigging products are fundamental tools handed across a comprehensive range of industries. These equipment support satisfactory and powerful cleansing, analysis, and maintenance of passages and other cylindrical buildings. Pigging requires driving tailored gadgets known as pigs through pipes to carry out multiple functions. Common types of industrial pigging equipment comprehend cleaning pigs, inspection pigs, and transit pigs. Cleaning pigs are crafted to clear debris, build-up, and dirt from pipelines. Inspection pigs are loaded with apparatus that collect information about the shape of pipe shells. Transport pigs are employed to deliver fluids through pipelines. The use of industrial pigging products yields numerous gains, such as minimized downtime, heightened pipeline strength, and bolstered operational capability. These devices are broadly installed in fields such as oil and gas, water treatment, chemical production, and food manufacturing.Pipeline Pigging: An Exhaustive Guide

Pipeline pigging is an critical approach used within the oil and gas sphere to examine pipelines. This mandatory procedure requires placing specific instruments, denoted as pigs, into the tube. Pigs are created to move along the stretch of the pipeline, accomplishing various responsibilities.

Multiple types of pigs are on hand, each engineered for a separate target. Common uses of pipeline pigging include examination for defects, purging, and surface treatment.

- Merits of Pipeline Pigging

- Footprints on Operational Efficiency

- Divisions of Pipeline Pigs

Reliable Sanitation through Pigging Solutions

Pigging processes supply a proven answer for preserving sanitation inside channels. These arrangements apply unique apparatuses that progress through the pipeline sequence, quickly eradicating layers. The practice is especially rewarding for branches that need rigorous purity regulations. Pigging methods yield a low-expense and quick approach for sterilizing equipment, minimizing the hazard of defilement.

Appointing Pigging Gear for Dedicated Wants

Pigging devices serves a crucial role in productive pipeline work. When deciding upon pigging devices, it is critical to consider the particular expectations of your operation. This requires evaluating details such as pipeline thickness, flow volume, product kind, and cleaning goals.

Different pigging options are obtained, each fabricated for distinct uses. For example, some pigs are built for checking, while others are deployed for clearing pollutants or segmenting product loads.

As well, pigging machinery materials should be agreeable with the shipped substance.

It is typically recommended to consult a technician in pigging systems to make certain that you elect the most proper machinery for your specific demands.

Conduit Maintenance Methods - A Benefit-Focused Approach

Conduit cleansing setups provide a comprehensive selection of virtues for fields built upon pipelines. By competently sanitizing and reviewing internal pipelines, pigging systems boost operational capability and curtail maintenance budgets.

A main positive of pigging systems is their capacity to extract scale such as crust, debris, and degradation residues. This regular cleaning secures fluid pipeline movement and obviates costly downtime.

Also, pigging systems can be employed to assess the soundness of pipelines, detecting prospective faults before they spread into significant problems. This strategic method assists to expand viability of pipelines and shrink overall maintenance expenditures.

Securing Hygiene in Pigging Functions

Piggy breeding methods rely greatly on appropriate hygiene procedures to restrain the spread of pathogens. Observing rigorous hygiene procedures enhances a healthy atmosphere for pigs, whereby causes advanced health outcomes and production.

Detailed cleaning and disinfection of premises is critical to eliminate the amount of harmful bugs. Appropriate residues management moreover operates a fundamental part in securing hygiene.

As sanitary pigging systems well, {workers