Under circumstances complex fin tube engineering and fabrication, collaborating with genuine consultants is required. These experienced finned tube fabrication professionals possess a detailed knowledge of heat transfer principles, component characteristics, and the innovative methods for creating efficient heat exchangers. They attend to everything from initial drafting and mock-up creation to mass output and precise validation. Opting for the right tube bundle fabrication expert can positively affect the efficiency and persistence of your apparatus.

Refined Ribbed Hollow Sections

Up-to-date process functions frequently demand highly efficient thermodynamic transmission, and state-of-the-art finned hollow bodies are fundamental to achieving this. These fragments include specially designed ridge geometries, frequently leveraging intricate formulas to enhance the surface available for power exchange. Assembly techniques may comprise casting, accompanied by careful fin creation and sporadically a distinctive surface layering to further improve output. Choosing the compatible finned channel format is influenced on the particular performance factors, notably material attributes, caloric measures, and pressure degrees.

Specialized Augmented Alloyed Hollow Configurations

Tackling challenging temperature-related management necessities? Our qualified team formulates custom-finned copper pipe solutions precisely to your application. We implement advanced building techniques and meticulous calculations to augment warmth movement efficiency. Whether you're in the mechanical sector, or need high-performing cooling within a sensitive system, our augmented copper channels can ensure enhanced performance. We analyze factors such as medium circulation rates, surrounding temperatures, and morphological constraints intended for produce a truly unique and competent design.

Authorities in Aluminum Fin Tube Services

For long durations, we've been dedicated to providing unparalleled expertise in profiled aluminum tubing design, manufacturing, and placement. As leading professionals, we offer a comprehensive portfolio of services, catering to a wide spectrum of industries, including air handling, power generation, and chemical treatment. Our division of expert engineers retains a broad understanding of heat migration principles and compound science, ensuring that every task we undertake delivers optimal output and lifespan. We believe ourselves on delivering bespoke approaches that precisely cope with our clients’ unique specifications. Whether you require coolant exchanger repair, renewal, or a full system design, our commitment to outstanding caliber remains unwavering. Speak with us today to evaluate your unique challenges.

Amplified Tube Construction and Maintenance Solutions

Enhancing thermal exchange efficiency is paramount in countless realms, and that's where specialized advanced tube development and consulting solutions truly shine. We extend comprehensive remedies encompassing everything from initial thought to full-scale application. Our staff of experienced masters leverage advanced simulation techniques and realm best protocols to design personalized finned tube structures for a wide array of difficult environments. Whether you're seeking to augment effectiveness, minimize usage costs, or confront specific engineering obstacles, our improved tube expertise guarantees maximum results. We moreover offer ongoing monitoring solutions to ensure ongoing functional integrity.

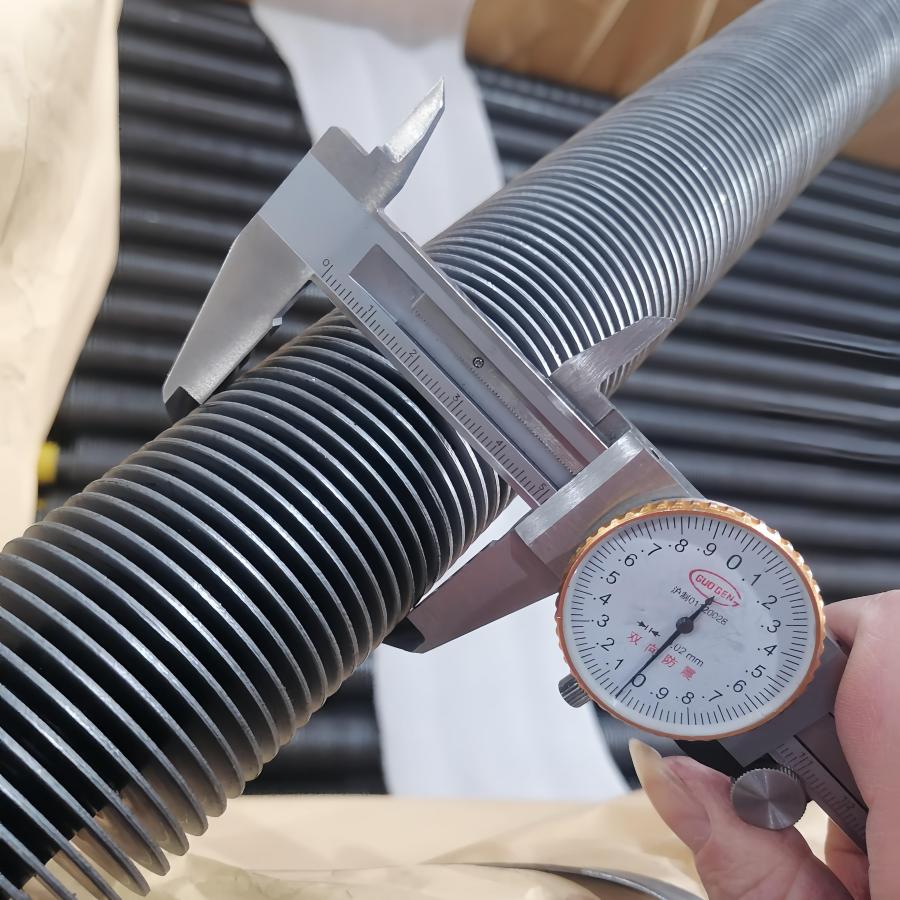

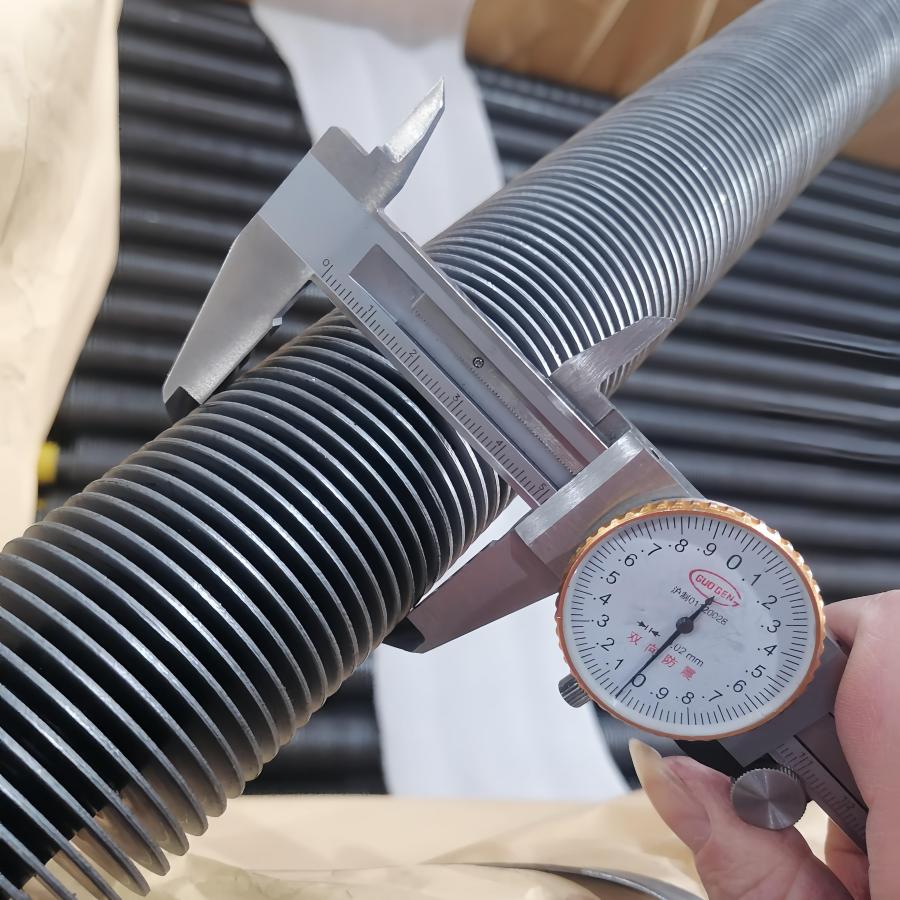

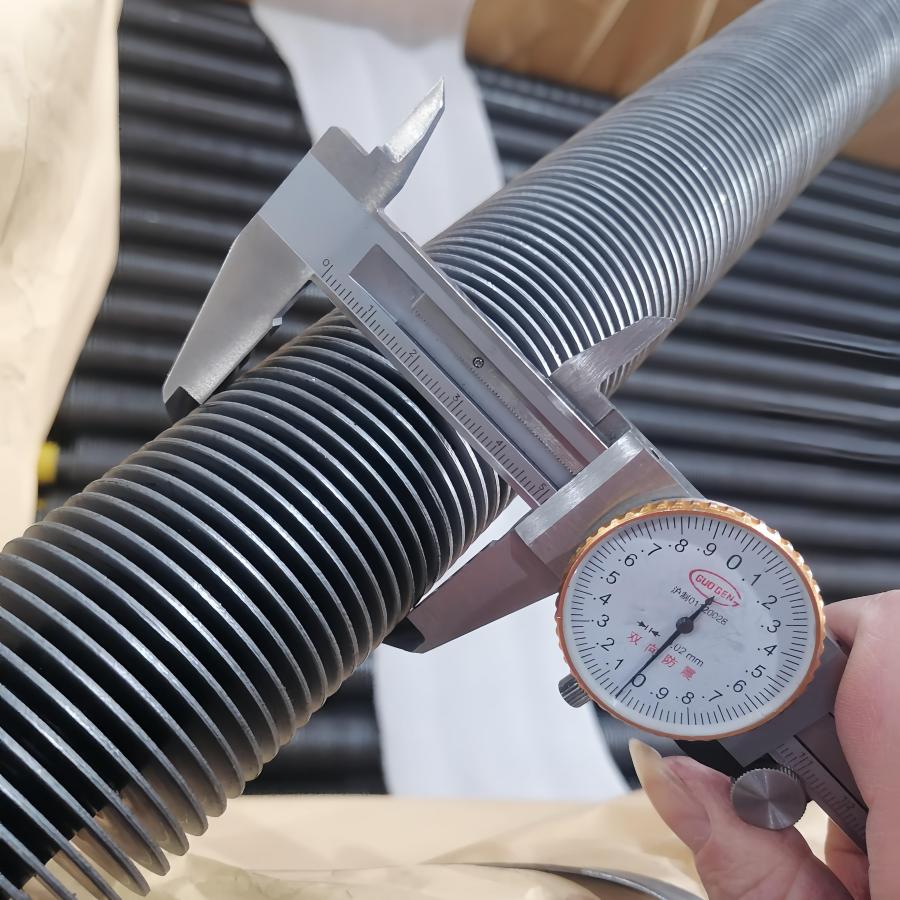

Leading Precision Radiating Tube Building

The expectations of modern heat transfer systems are initiating a shift towards highly advanced extended tube approaches. Traditionally, ordinary fin forms were allowable, but now applications in electronics and energy processing necessitate particularly tight tolerances and involved geometries. This involves exact bending of fins directly onto the tube core, often utilizing leading-edge cryogenic treatment equipment to acquire the desired radiator extent, separation, and form. Over and above, the constituent selection plays a crucial function, with bespoke mixtures frequently applied to boost thermal capability while maintaining formative sturdiness. Grade supervision methods are also vital to confirm steady textured tube level.

Extended Copper Pipe for Heat Exchangers

Cutting-edge heat dispersion systems frequently use finned copper conduit as a crucial aspect in heat exchangers. The inclusion of fins, typically made from aluminum, significantly magnifies the surface field available for heat conduction, leading to a higher efficient heat swap. These improved copper pipelines are usually found in applications ranging from technical processes, such as finned tube heat exchanger chilling machinery, to occupational HVAC systems. The notable thermal heat diffusion of copper, coupled with the expanded surface area coverage provided by the fins, generates in a significantly effective method for managing heat. Different fin structures, including planar and curved, supply varying degrees of performance refinement depending on the precise application’s criteria.

Cutting-edge heat dispersion systems frequently use finned copper conduit as a crucial aspect in heat exchangers. The inclusion of fins, typically made from aluminum, significantly magnifies the surface field available for heat conduction, leading to a higher efficient heat swap. These improved copper pipelines are usually found in applications ranging from technical processes, such as finned tube heat exchanger chilling machinery, to occupational HVAC systems. The notable thermal heat diffusion of copper, coupled with the expanded surface area coverage provided by the fins, generates in a significantly effective method for managing heat. Different fin structures, including planar and curved, supply varying degrees of performance refinement depending on the precise application’s criteria.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum enhanced tubes offer a compelling combination of slimline construction and remarkable effectiveness, making them ideal for a large range of process heat transfer operations. Their unique configuration—featuring aluminum edges attached to the tube exterior—significantly raises the heat exchange potential without adding substantial size. This translates to lower energy spending and improved overall system steadiness. Consequently, these tubes are frequently appointed in HVAC units, refrigeration, and other heat convection processes where minimizing weight and maximizing caloric transfer are paramount matters.

Fin Tube Constituent Options: Copper & Aluminium

In the event that choosing finned tube material, engineers frequently consider copper and aluminum. Copper offers exceptional decay tolerance and superior energy transfer, making it perfect for applications where optimal heat distribution is paramount, such as in temperature regulation systems. However, copper's heightened valuation and probable for galvanic corrosion with other materials can be limiting hindrances. Conversely, aluminum provides a significantly lower charge and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Optimizing Heat Conveyance with Finned Hollow Bodies

The output of heat systems frequently hinges on the design and use of finned tubing. These structures significantly amplify the surface area available for heat flow, allowing for a much greater extraction of heat compared to simple, unfinned sections. The improvement process involves a complex interplay of factors, including fin configuration – such as fin dimension, spacing, and gauge – as well as the element of both the fins and the foundation hollow bodies themselves. Careful consideration of the substance flow characteristics, whether it's air or a coolant, is also paramount to ensure that the heat rejection isn’t restricted by boundary layer effects or uneven arrangement of the working coolant. Ultimately, a well-designed finned hollow body array delivers a considerable improvement in overall thermal productivity within a given space.

Reliable Finned Tube Networks for Production Applications

Satisfying the demands of demanding manufacturing environments necessitates hardy heat transfer devices. Our finned tube lines are engineered for exceptional durability, providing dependable heat distribution in a range of applications, from chemical-processing processing to HVAC control. Constructed from high-end materials and featuring advanced wear endurance techniques, these units minimize overhaul downtime and maximize operational functionality. The customized fin pattern promotes amplified heat conveyance, even under severe operating contexts.